Step-by-Step Guide to Preventing Weld Undercut in Different Metals

Wiki Article

Comprehending the Causes and Solutions for Undercut Welding in Steel Manufacture Procedures

In the world of steel fabrication procedures, the event of undercut welding positions a significant challenge that requires a thorough understanding of its causes and viable services. The elaborate interplay of various factors throughout welding procedures can result in this unwanted phenomenon, affecting the architectural integrity and overall top quality of the bonded joints - Preventing weld undercut. By exploring the source of undercut welding and discovering efficient restorative steps, producers can raise the criterion of their handiwork and make certain the manufacturing of perfect metal componentsUsual Root Causes Of Undercut Welding

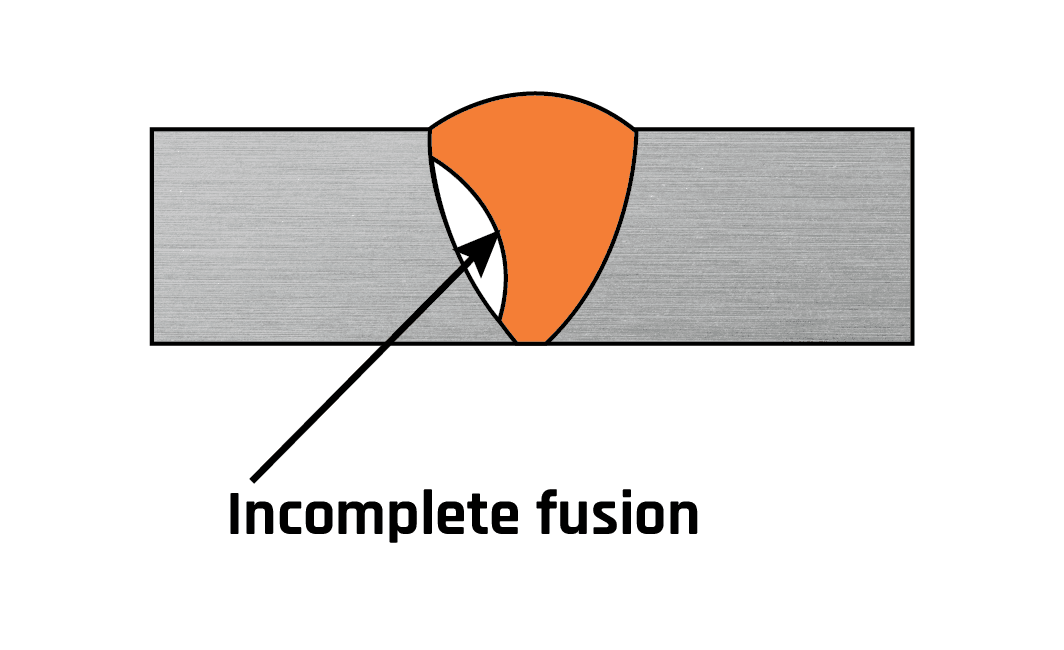

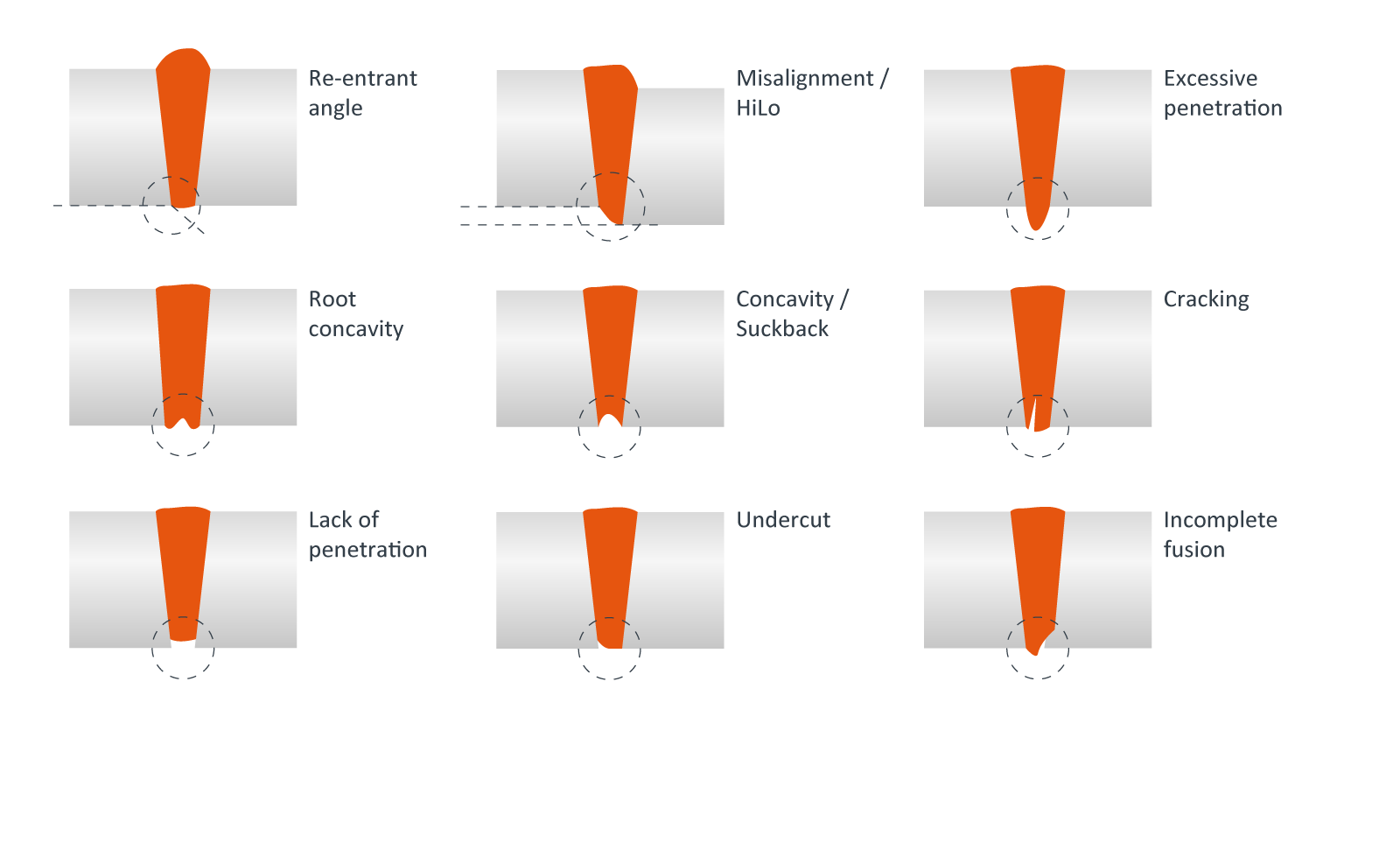

Frequently overlooked in steel manufacture, undercut welding occurs as a result of numerous factors that require thorough interest and expertise to be successfully alleviated. One common root cause of undercut welding is extreme warmth input. When the warm input is expensive, it can lead to the melting and succeeding erosion of the base product along the edges of the weld joint, creating a groove or undercut. Furthermore, improper welding techniques, such as making use of the wrong welding angle or take a trip speed, can additionally add to damage development. Inadequate securing gas coverage is an additional essential variable that can lead to damaging. Inadequate gas coverage stops working to protect the weld swimming pool effectively, resulting in oxidation and undercut issues. Furthermore, the selection of welding specifications, such as voltage, existing, and wire feed rate, plays a significant role in the event of undercut welding. Understanding these typical reasons is essential for applying preventive steps and making certain premium welds in steel fabrication processes.

Influence of Incorrect Welding Parameters

Incorrect welding specifications can significantly endanger the integrity and top quality of bonded joints in metal construction procedures. The impact of inaccurate welding specifications shows up in various methods, leading to architectural weak points and problems in the bonded components. Thorough focus to welding parameters is vital to make certain the production of top quality welds with the preferred mechanical properties and structural integrity.Impact of Improper Torch Angle

Incorrect lantern angle in welding procedures can dramatically impact the quality and integrity of the last weld joints in steel manufacture procedures. The lantern angle plays an essential function in establishing the warmth input and circulation throughout welding. When the lantern angle is wrong, concerns such as damaging can emerge. Damaging is a typical welding flaw where a groove creates along the weld toe, deteriorating the joint and endangering its architectural stability.A torch angle that is too steep can lead to not enough infiltration, incomplete fusion, and increased spatter. On the other hand, a lantern angle that is as well shallow can result in too much infiltration, burn-through, and distortion of the base material. Preventing weld undercut. Proper lantern angle is crucial for making sure constant weld quality, toughness, and look

To avoid undercutting and various other flaws brought on by improper lantern angles, welders should be educated to preserve the appropriate lantern angle throughout the welding procedure. Regular surveillance and modification of torch angles throughout welding can help attain sound welds with minimal issues.

Function of Inadequate Welding Techniques

Another aspect of inadequate welding techniques is improper weld preparation. Inadequate cleaning of the base steels, wrong joint layout, or not enough side prep work can all add to undercut welding. Inadequate shielding gas coverage or making use of the incorrect kind of gas can result in incomplete fusion and the development of undercut issues.

To attend to the function of inadequate welding techniques in steel construction processes, it is necessary to offer comprehensive training for welders. Correct education and learning on welding specifications, joint preparation, and securing gas choice can try this web-site help protect against undercut welding and make sure premium welds in metal manufacture jobs.

Effective Solutions for Undercut Welding

Resolving undercut welding in metal fabrication calls for executing effective options to enhance weld top quality and structural integrity. One of the primary options to fight undercut is to readjust welding criteria such as voltage, current, and travel rate to ensure correct heat input and blend. By fine-tuning these settings, welders can prevent extreme melting of the base steel and filler material, lowering the probability of undercut development.Furthermore, correct joint preparation is crucial in stopping undercut. Ensuring clean base steel surfaces devoid of contaminants and utilizing the ideal bevel angle can help promote far better weld penetration and minimize the threat of undercut - Preventing weld undercut. Employing appropriate welding strategies, such as weaving or oscillating the torch, can additionally assist in distributing warm equally and loading the weld joint sufficiently, decreasing the possibility of undercut problems

Moreover, picking the correct welding consumables, including electrodes and filler metals, is necessary in minimizing undercut. Using materials with suitable chemical structures and mechanical residential or commercial properties can add to accomplishing audio welds with marginal undercut. Normal inspection and quality assurance steps ought to likewise be carried out to identify and resolve undercut issues promptly, ensuring the overall integrity of fabricated metal components.

Verdict

In conclusion, recognizing the reasons and remedies for undercut welding in steel manufacture procedures is vital for accomplishing top notch welds. By attending to usual reasons such as inaccurate welding specifications, incorrect torch angle, and inadequate welding strategies, welders can protect against damaging and guarantee strong, durable welds. It is important to pay attention to these variables and carry out efficient services to boost the total welding procedure and final item top quality.

Report this wiki page